NTU and Harvard scientists collaborate to develop innovative solution to keep produce fresh longer

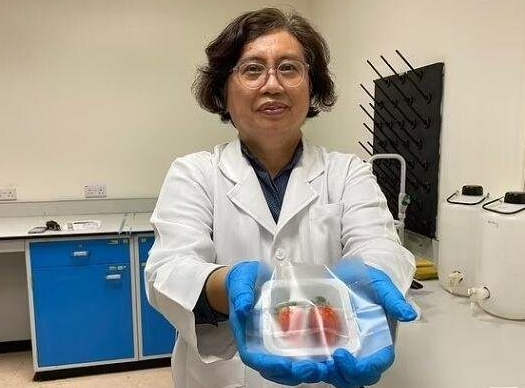

Researchers from Nanyang Technological University (NTU) and Harvard T.H. Chan School of Public Health have developed a cutting-edge biodegradable food packaging that significantly extends the freshness of fruits, such as strawberries, surpassing traditional synthetic plastic packaging.

The key ingredient in this packaging is zein, a protein derived from corn gluten meal, a byproduct of corn ethanol production. This innovative material is created using a method called electrospinning, which uses electric force to form fibres. These fibres are infused with zein, natural antimicrobial compounds, cellulose, and acetic acid, resulting in a waterproof and antimicrobial packaging solution. The material responds to changes in humidity and the presence of bacteria by releasing small amounts of natural compounds that can combat harmful microbes like E. coli, Listeria, and fungi.

According to Mary Chan, Director of NTU’s Centre of Antimicrobial Bioengineering and co-leader of the project, this intelligent antimicrobial release mechanism ensures protection only when necessary, minimising chemical use and preserving the natural integrity of the food.

The packaging has proven to extend the shelf life of fresh produce. For example, strawberries wrapped in the biodegradable material stayed fresh for three days longer than those stored in conventional plastic packaging, with mould only appearing after seven days. This could significantly reduce food waste, which is a major global concern. Philip Demokritou, co-lead of the project, emphasised that biodegradable, non-toxic food packaging materials could be a key solution to improving food safety and minimising waste.

Beyond strawberries, this biodegradable packaging can be applied to a wide range of products, including other fruits, fresh produce, ready-to-eat foods, and even raw meat. As the technology progresses, it holds promise for becoming a sustainable alternative to traditional plastic packaging, which is a significant contributor to environmental pollution. In Singapore alone, plastic accounted for 55% of the 1.76 million tonnes of domestic waste in 2018, with a third of that being packaging waste.

The team is actively working on scaling up their technology and hopes to partner with industry leaders to bring this innovative solution to market within the next few years, helping to reduce both food spoilage and plastic waste globally.